CONCRETE SLABS AND

FLEXIBLE PAVEMENT SOLUTIONS

Looking for a concrete slab, hardstand, concrete apron, car park, shed floor or pavement solution that's faster, cleaner, greener and more affordable? Welcome to Rombus, the flexible pavement solution that delivers the same functionality as asphalt but with exceptional strength and wear properties.

Our innovative technology is the first of its kind, featuring a hard concrete surface manufactured in Australia using recycled plastic materials. With Rombus, you can easily perform in situ placement and grid filling, saving you significant time and trouble compared to full-depth repairs. Enjoy a dust-free, gravel-free wearing course that outperforms traditional options with Rombus

HOW IT WORKS

Rombus is a game-changer in the pavement industry. Its unique design and composition make it ideal for high-traffic areas and harsh weather conditions, such as heavy rainfall. The recycled plastic material used in its production ensures that the product is sustainable and eco-friendly.

The installation process is straightforward and fast. The Rombus pavement system can be installed over an existing road surface or a prepared base course. Once installed, the system is durable and has low maintenance properties, reducing long-term costs and ensuring the longevity of the surface.

The Rombus flexible pavement solution offers a wide range of benefits over traditional pavement systems. Its dust-free and gravel-free composition creates a cleaner environment, reducing the amount of dust, dirt, and debris kicked up by traffic. This makes it ideal for areas where cleanliness and air quality are of utmost importance, such as hospital parking lots, schools, and other public areas.

Additionally, the Rombus system is resistant to chemicals and fuel spills, making it an ideal solution for areas with a high concentration of heavy vehicles, such as gas stations and loading docks.

Overall, the Rombus flexible pavement solution offers superior strength, durability, and sustainability, making it an ideal solution for a wide range of applications.

WHY ROMBUS

We are Stronger

Faster

Affordable

And Greener

IN ACTION

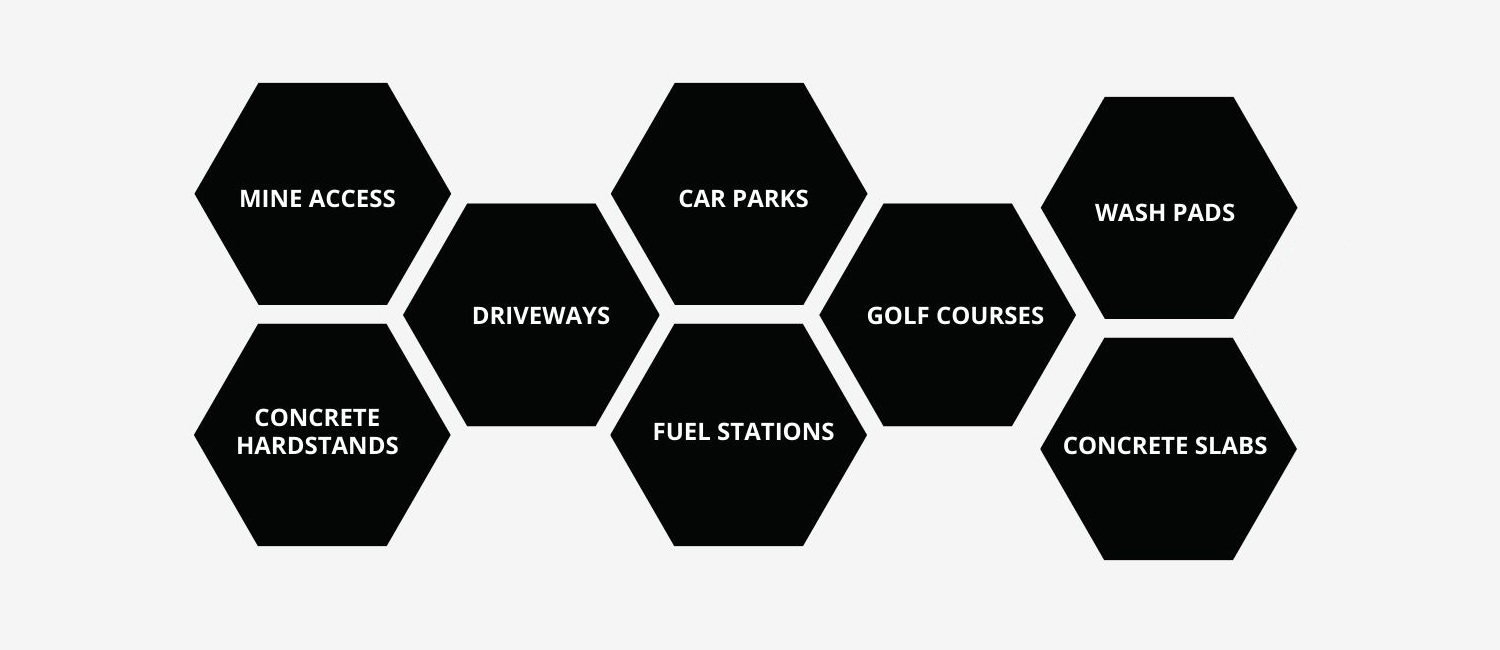

USES INCLUDE

Mining Oil and Gas

Construction

Farming and Agriculture

landscaping and Domestic

COST EFFECTIVE

CONCRETE SLABS

HOW IT WORKS

We are leading the way in carbon avoidance

in the concrete industry

Cement production is the world's single biggest industrial cause of carbon pollution, responsible for 8% of global emissions. That's as much as the global car fleet.

Rombus was formed in 2019 with the vision of creating a cleaner greener future within the concrete industry by introducing a revolutionary rapid deployment recycled plastic grid system that is stronger, faster, cheaper, and greener than traditional methods.

Based in Perth WA with a national footprint, the ground-breaking innovation is 100% Australian designed, manufactured, and owned. Each 1 m2 grid uses 5.4 kg of Australian recycled plastic and is a mere 4cm thick, however, when filled with 32MPa concrete (10mm aggregate) it has a rating of over 10,000 tonnes per square metre.

WHY ROMBUS

We are Stronger

And Faster

Much Cheaper

And Greener

Welcome to our webpage on how to reduce your concrete costs and slash your carbon footprint!

If you're looking to save money on your concrete projects and reduce your impact on the environment, we've got a solution for you. With the Rombus grid solution, you could save up to 60% on your concrete costs while creating a modular pavement hardstand that is stronger than traditional concrete slabs.

But that's not all - using the Rombus grid can also greatly reduce your carbon footprint. By cutting down on cement usage, you could reduce associated carbon emissions by anywhere from 65% to 90%. That's a big win for the environment!

So why not give the Rombus grid solution a try? You'll save money, create a stronger surface, and help reduce your impact on the planet. Contact us today to learn more

How does a saving of up to 60% on your concrete costs sound?

Old Roman cobblestone roads have lasted thousands of years. This forms the basis of the Rombus grid solution. When filled with concrete, the Rombus grid form's a modular pavement hardstand that is stronger than traditional concrete slabs.

It's also cheaper, much faster to install and greener. With a reduction in cement and associated carbon emissions of between 65% and 90%, it's a win for the environment..

USES INCLUDE

Mining Oil and Gas

Construction

Farming and Agriculture

landscaping and Domestic

IN ACTION

WASH PAD INSTALL

Direct seeding and harvesting equipment in WA recently called on J & R contracting to install a wash pad. Rombus grid was used and the entire install was quick and efficient. Note the ability of the concrete truck to operate directly on the grid eliminating the need for expensive pumps and additional equipment onsite.

WIDE VARIETY OF APPLICATIONS

The Rombus grid is inspired by the ancient Roman cobblestone roads that have withstood the test of time. When filled with concrete, it forms a strong and durable surface that is perfect for driveways, walkways, and more. Plus, it's much faster and easier to install than traditional concrete slabs.