A Fair Question in Heavy Duty Environments

When people first see Rombus, the most common question from commercial and industrial clients is simple:

Can it actually handle heavy machinery

In Australia, pavements are exposed to extreme loads. Mining equipment, civil machinery, trucks, forklifts, and constant traffic place enormous stress on ground surfaces. Traditional concrete slabs have been the default solution for decades, but cracking, joint failure, and downtime are common.

Rombus was developed specifically to operate in these environments.

What Heavy Machinery Really Does to Concrete

Heavy machinery does not just apply weight.

It applies point loads, dynamic movement, heat, and repeated stress.

Traditional slabs rely on thickness and reinforcement to resist this. When the load exceeds what the rigid slab can absorb, stress concentrates and cracking occurs. Once cracks form, water ingress, edge failure, and surface breakdown follow.

This is why slab repairs are common in industrial yards, access roads, and mine sites.

How Rombus Is Designed for Heavy Loads

Rombus is a flexible concrete pavement system, not a rigid slab.

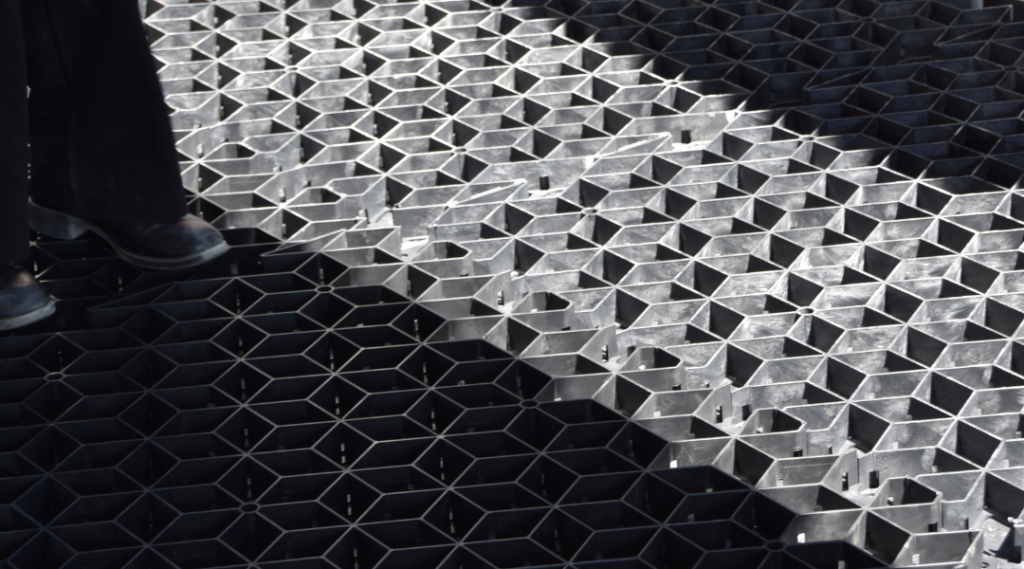

Each grid measures 1000 x 1000 millimetres and 40 millimetres thick, manufactured from 96 percent recycled polypropylene. Once installed, the grid is filled with a 32 MPa concrete mix using 10 millimetre aggregate.

The key difference is structural behaviour.

Instead of acting as one rigid mass, Rombus distributes load across its modular grid structure. Stress is spread through the system rather than concentrating at a single point.

This allows the pavement to handle heavy machinery without the cracking and joint failure seen in traditional slabs.

Load Capacity Explained Simply

When filled and installed correctly, Rombus has been tested beyond 10,000 tonnes per square metre.

This figure is not theoretical. It reflects the system’s ability to handle extreme compressive loads when supported by proper ground preparation.

For comparison, this places Rombus well within the performance range required for:

- Heavy vehicle access routes

- Industrial hardstands

- Mining and resource sites

- Commercial yards and service areas

Rombus achieves this performance through design, not bulk material thickness.

Why Flexibility Matters Under Machinery

Heavy machinery creates movement.

Acceleration, braking, turning, vibration, and heat all generate stress.

Rigid slabs resist this movement until they fail.

Rombus absorbs and distributes it.

The modular grid allows small amounts of controlled movement, preventing long continuous stress paths. This is why Rombus performs in environments where slabs routinely crack.

Built for Australian Conditions

Australia presents some of the toughest conditions for concrete pavement in the world.

High ambient temperatures, large temperature swings, reactive soils, and heavy axle loads are common across mining, civil, and industrial sites.

Rombus was designed and tested in Australia for these exact conditions:

- Lower thermal mass than thick slabs

- High UV and chemical resistance

- Modular structure that works with ground movement

- Reduced maintenance and easier repair

The grids are manufactured in Adelaide, with head office in Perth, and designed for long term performance in harsh environments.

Where Rombus Is Used With Heavy Machinery

Rombus is suitable for:

- Mining access ways and laydown areas

- Industrial yards and loading zones

- Heavy vehicle hardstands

- Plant and equipment pads

- Expansion areas where demolition is impractical

Because the system can be installed over prepared ground or structurally sound existing concrete, it is also ideal for upgrades where downtime needs to be minimised.

TLDR;

Yes, Rombus can handle heavy machinery.

It was not designed as a decorative surface or light duty alternative. It was engineered as a heavy duty flexible concrete pavement system that performs where traditional slabs struggle.

For industrial, commercial, and mining applications across Australia, Rombus offers a smarter way to build concrete pavements that last.