APPLICATIONS

CONCRETE SLAB INSPECTION

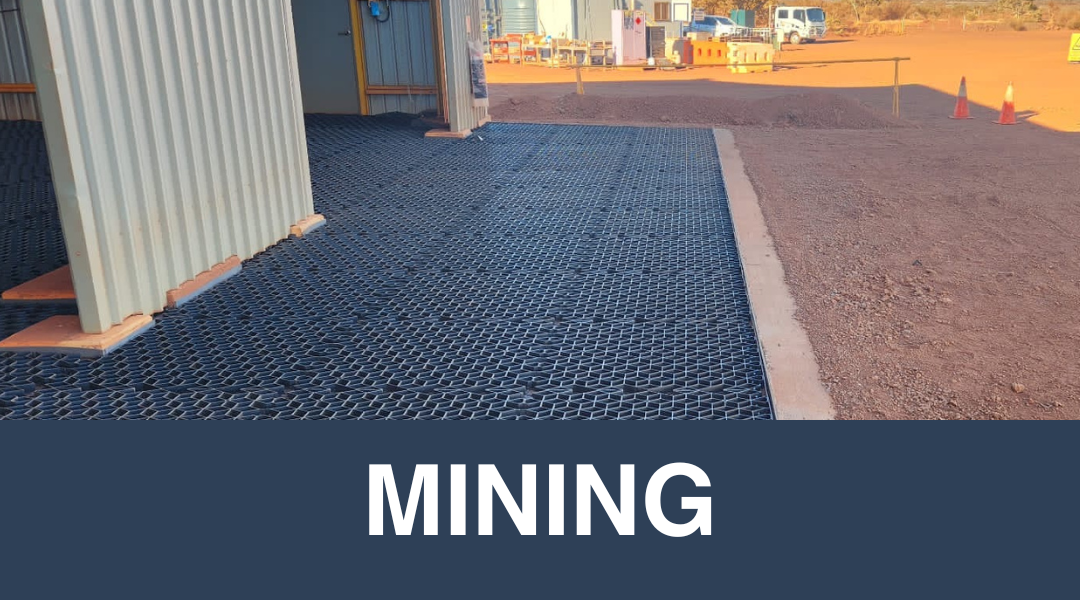

Concrete damage is a major issue that can arise when heavy machinery is used on concrete hardstands. This damage can occur due to a variety of factors, such as the weight of the machinery, the frequency of use, and the condition of the concrete.

The weight of heavy machinery can put a significant amount of pressure on the concrete hardstand. This pressure can cause the concrete to crack or develop potholes, which can make the surface uneven and hazardous. If left unchecked, the damage can worsen over time and require costly repairs or even the replacement of the entire hardstand.

In addition to the weight of the machinery, the sharp edges of equipment can also cause damage to the concrete surface. The scraping and rubbing of sharp edges against the concrete can cause abrasions and scratches that weaken the surface and make it more susceptible to further damage.

Other factors that can contribute to concrete damage include weather conditions, the age and condition of the concrete, and the frequency of use of heavy machinery on the hardstand. Extreme temperature changes, exposure to moisture, and freeze-thaw cycles can all weaken the concrete, making it more prone to damage. At only 4 cm thick and subject to constant abuse for the last 2 years we are happy to report the slab is in great condition.